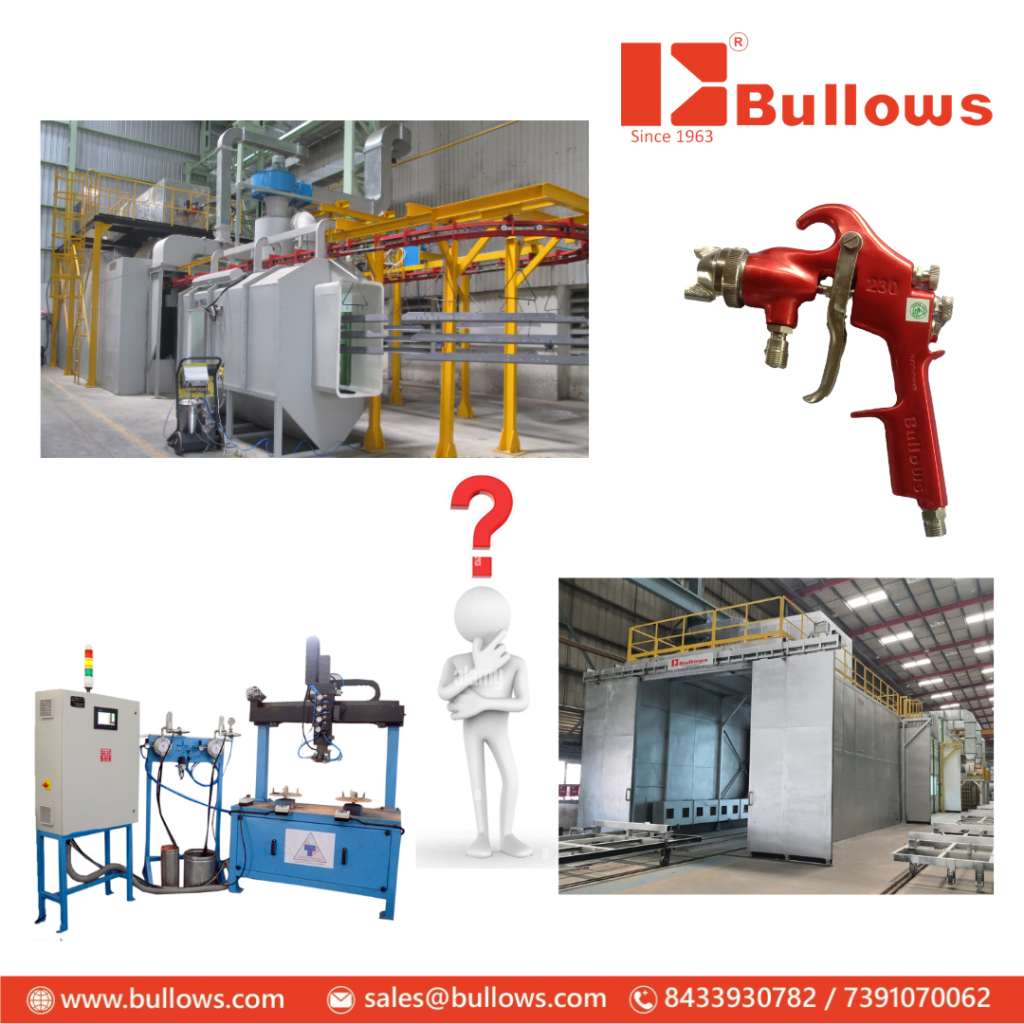

How to Choose the Right Painting Equipment

for Your Needs: A Detailed Guide

Introduction:

Choosing the right painting equipment can be a daunting task, especially with the wide variety of options available on the market today. Whether you are setting up a new paint shop, upgrading your existing equipment, or tackling a specific painting project, selecting the

appropriate tools is crucial for achieving high-quality results efficiently. In this guide, we’ll walk you through the key considerations and steps to help you choose the right painting equipment for your needs.

Understand Your Painting Requirements:

Before diving into the specifics of different painting equipment, it’s important to clearly understand your painting requirements. Ask yourself the following questions:

What type of surfaces will you be painting? (e.g., metal, wood, plastic)

What is the scale of your project? (e.g., small-scale, large industrial applications)

What kind of paint or coating will you be using? (e.g., solvent-based, water-based, powder coating)

What level of finish quality do you need? (e.g., high gloss, matte, textured)

Do you have any specific environmental or safety requirements? (e.g., low VOC emissions, explosion-proof equipment)

Understanding your specific needs will help you narrow down the types of equipment that will be most suitable for your application.

2. Types of Painting Equipment

-

a. Spray Guns

Spray guns are versatile tools commonly used for a variety of painting applications. They can be categorized into several types:

- Conventional Spray Guns: Use high pressure to atomize the paint. Best for projects requiring a fine finish, but can produce overspray and waste.

- HVLP (High Volume Low Pressure) Spray Guns: Deliver a higher volume of paint at lower pressure, reducing overspray and waste, making them ideal for detailed and precision work.

- Airless Spray Guns: Use high pressure to atomize paint without air. Suitable for large surfaces and thick coatings, offering fast application with minimal overspray.

- Electrostatic Spray Guns: Use an electrostatic charge to attract paint to the surface, improving transfer efficiency and reducing waste. Ideal for metal surfaces and industrial applications.

b. Spray Booths Spray booths provide a controlled environment for painting, ensuring consistent quality and safety. Key types include:

-

- Downdraft Booths: Pull air from the ceiling to the floor, providing better air filtration and a cleaner finish.

- Semi-Downdraft Booths: Combine features of both cross draft and downdraft booths, offering a balanced solution.

- Cross-draft Booths: Draw air horizontally across the painting area. Cost-effective but may result in uneven airflow.

- Powder Spray Guns: Use compressed air to spray powder onto the surface. Look for features like

adjustable flow rates and electrostatic charging for better control. - Powder Coating Ovens: Cure the powder-coated items. Ensure the oven size and temperature range match

your application needs. - Pretreatment Systems: Clean and prepare surfaces before coating, enhancing adhesion and finish

quality. - Robotic Painters: Provide precise and repeatable application, ideal for complex geometries and high-volume production.

- Conveyor Systems: Transport items through various stages of the painting process, streamlining production flow.

c. Powder Coating Equipment

Powder coating is a dry finishing process that involves applying a powder to a surface and then curing it under heat. Key components include:

d. Automated Painting Systems

For large-scale or repetitive tasks, automated painting systems offer high efficiency and consistent results. Options include:

3. Key Considerations for Selecting Painting Equipment

a. Quality and Durability

Investing in high-quality, durable equipment ensures long-term reliability and reduces maintenance costs. Look for reputable brands and read reviews to gauge performance and longevity.

b. Compatibility with Paint Types

Ensure the equipment you choose is compatible with the types of paint or coatings you plan to use. Different paints may require specific nozzles, pressure settings, or curing methods.

c. Ease of Use and Maintenance

User-friendly equipment reduces training time and enhances productivity. Additionally, consider the ease of maintenance and availability of spare parts to minimize downtime.

d. Safety Features

Safety is paramount in any painting operation. Look for equipment with built-in safety features such as pressure relief valves, automatic shut-off mechanisms, and proper ventilation systems.

e. Cost and Budget

While it’s important to stay within budget, avoid compromising on quality. Consider the total cost of ownership, including initial purchase price, maintenance, and operating costs.

f. Environmental Impact

Consider the environmental impact of your painting equipment. Opt for energy-efficient models and equipment that minimize paint waste and emissions.

4. Making the Final Decision

After considering the above factors, compile a shortlist of equipment options that meet your needs. Reach out to manufacturers or distributors for demonstrations or trials to see the equipment in action. Don’t hesitate to ask for references or case studies from similar applications.

Conclusion:

Choosing the right painting equipment requires careful consideration of your specific requirements, the types of equipment available, and key factors such as quality, compatibility, ease of use, safety, cost, and environmental impact. By following this detailed guide, you can make an informed decision that will help you achieve optimal results for your painting projects.

For more expert advice and to explore Bullows’ range of high-quality painting equipment and turnkey solutions, feel free to contact us or visit our website. We’re here to help you find the perfect tools for your needs.

Experience the Bullows Advantage Today

Contact us today to learn more about Bullows Spray Guns, Tanks & Paintshop Accessories and how they can revolutionize your industrial coating applications. Experience precision, efficiency, and reliability like never before with Bullows – your trusted partner for excellence in spray gun technology.

Phone No.: +91 84339 30782 / +91 73910 70062

Mail ID: sales@bullows.com

Website: www.bullows.com

WhatsApp: https://lnkd.in/dn2M7X_c