Pre-Treatment Plant

It is a system or a way by which a component either steel or aluminium or plastic or any other has been thoroughly cleaned.

material during machining works also passes through a series of machines for cutting, grinding etc. During all the above processes oil is been added as a coolant to reduce the abrasion between the tools and the shape to be formed, oil is also added after casting work is completed to save the components from getting rusted. These oils have a thicker density and cannot be removed easily by cotton waste wiping, if such components are to be painted or powder coated, there are high chances of complete failure of paint or powder film. Therefore pretreatment system comes into to picture to remove the deficiency due to oils and increase the efficiency of the painting system or powder coating system.

Bullows has extensive experience in manufacturing & installation of cost-effective Pre-treatment Plants in many industrial segments.

A thorough material Pre-treatment is the fundamental prerequisite of any high-quality coating. Wet or Dry pre-treatment, depends on the material to be coated.

Benefits

1] Consistent quality of coatings to meet specification requirements

2] Significant improvements in paint and powder coating performance.

3] Improved corrosion resistance under the organic coating surface

4] Provide increased adhesion & improved flexibility

4] Adhesive bonding & laminating is made possible by specific pretreatment

5] Increases SCRATCH and IMPACT resistance.

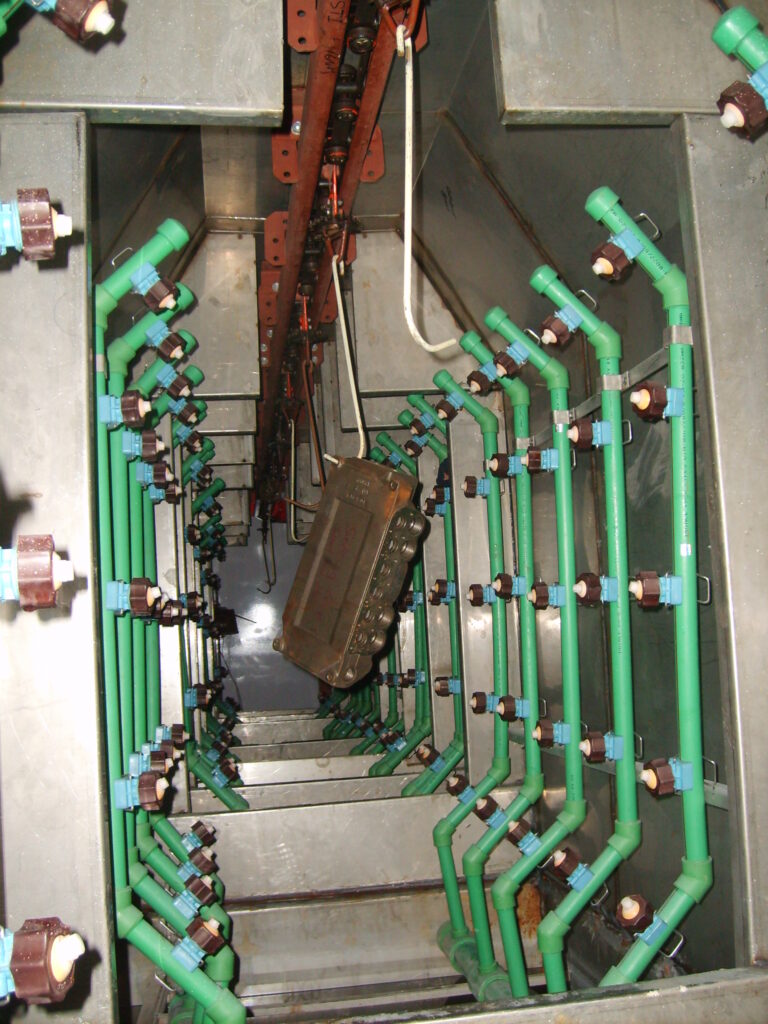

Spray Type

Spray Pretreatment systems are useful for standard components with high volume of daily requirements. A spray pretreatment plant for powder coating or painting has a higher financial necessity for such installation. The usage of lower manpower in such systems helps to maintain the consistent quality of the spray phosphating plant.

Dip Type

Dip Pretreatment plants are more useful when there is a lack of space or lack of budget and also for very large components that can not be handled automatically or with the help of a conveyor system.

Bullows has a completely professional team to work out a detailed scheme using the right materials for the construction of the tanks so that the materials used give the best performance & long life. Our experience and constant updating of technology in the field of pretreatment process help our customers to get the right output and hassle-free system