A General guide on dry paint booth maintenance:

Introduction:

Welcome to our comprehensive guide on Dry Paint Booth Maintenance. In the world of industrial painting and coatings, a well-maintained dry paint booth is a critical component for ensuring high-quality results, safety, and efficiency. This guide aims to provide you with a general understanding of the maintenance procedures that can help keep your dry paint booth in optimal condition. Whether you’re a seasoned

professional or a beginner in the field, this guide will serve as a valuable resource for you.

Steps to be taken for Dry Paint Booth Maintenance:

1. Regular Inspection: Schedule routine inspections of the paint booth components, including filters, ductwork, impeller blower, and lighting, to identify any signs of wear, damage, or malfunction.

2. Filter Replacement: Check and replace filters regularly according to the manufacturer’s recommendations. This typically includes primary and secondary filters to capture overspray and prevent contamination of the workspace.

3. Metal Baffle Filters are commonly used in paint booths as part of the filtration system to capture overspray and contaminants during the painting process. Here’s some information about metal baffle filters in paint booths:

Replacing metal baffle filters in a paint booth requires careful attention to ensure proper installation, safety, and continued

effectiveness of the filtration system. Here are some key considerations and steps to take during metal baffle replacement:

A. Shutdown Procedures: Before beginning the replacement process, shut down all equipment associated with the paint booth, including exhaust fans and ventilation systems, to prevent accidents and ensure safety.

B. Personal Protective Equipment (PPE): Wear appropriate PPE, including gloves and eye protection, to protect against cuts, sharp edges, and exposure to hazardous materials during the replacement process.

C. Assessment of Existing Filters: Inspect the existing metal baffle filters for signs of damage, wear, or excessive buildup of overspray. Note any areas that may require special attention during cleaning or replacement.

D. Preparation: Clear the area around the exhaust openings and ensure there is sufficient space to maneuver and access the filters. Gather all necessary tools and equipment for the replacement process.

E. Removal: Carefully remove the existing metal baffle filters from the paint booth exhaust openings, taking care not to damage surrounding components or surfaces. Use appropriate tools, such as wrenches or screwdrivers, to loosen and remove fasteners holding the filters in place.

F. Cleaning: The existing filters are reusable, clean them thoroughly using water, mild detergents, or specialized cleaning solutions. Remove any accumulated overspray, dirt, or debris from the filters’ surfaces and baffles.

G. Replacement: Install the new metal baffle filters securely into the exhaust openings, ensuring they are properly aligned and seated. Fasten them in place using the appropriate hardware and tighten securely to prevent air leaks.

H. Alignment and Sealing: Check for proper alignment of the filters within the exhaust openings and ensure there are no gaps or spaces where air could bypass the filtration system. Use gaskets or sealing materials as needed to create a tight seal around the edges of the filters.

I. Testing: After replacing the filters, perform a visual inspection to confirm they are installed correctly and securely. Once satisfied, restart the paint booth equipment and conduct a test run to verify proper airflow and filtration performance.

J. Documentation: Keep detailed records of the filter replacement process, including dates, maintenance activities performed, and any issues encountered. This information can help track filter lifespan and identify trends or areas for improvement in the maintenance program.

Overall, metal baffle filters are an effective and durable option for paint booth filtration, providing reliable overspray capture and helping to maintain a clean and safe working environment for painting operations.

4. Cleaning: Clean the interior surfaces of the paint booth regularly to remove accumulated overspray, dust, and debris. Use appropriate cleaning solutions and equipment to avoid damaging sensitive components.

5. Ductwork Inspection: Inspect the ductwork for any leaks, damage, or obstruction that may affect airflow and filtration efficiency. Repair or replace damaged ducts promptly to maintain proper ventilation.

6. Fan Maintenance: Ensure that exhaust fans are functioning correctly and are free from debris or buildup that could impede airflow. Lubricate fan motors as needed and replace worn-out parts to prevent breakdowns.

7. Lighting: Check and replace lighting fixtures as necessary to maintain adequate illumination within the paint booth. Clean light covers regularly to prevent reduced visibility due to dust and dirt accumulation.

8. Safety Equipment: Verify the functionality of safety features such as fire suppression systems, emergency stop buttons, and ventilation controls. Test these systems periodically to ensure they are ready for use in case of an emergency.

9. Training and Documentation: Provide training to personnel responsible for operating and maintaining the paint booth. Keep detailed records of maintenance activities, including inspection dates, filter replacements, repairs, and any issues encountered.

10. Environmental Compliance: Ensure compliance with environmental regulations governing the use and disposal of paint materials and waste. Properly manage and dispose of hazardous materials in accordance with local regulations.

11. Professional Service: Schedule periodic maintenance checks by qualified technicians to perform thorough inspections and address any complex issues or repairs beyond the scope of routine maintenance.

By following these maintenance practices, you can prolong the lifespan of your dry paint booth, minimize downtime, and maintain a safe and efficient working environment for painting operations.

Conclusion:

In conclusion, maintaining your dry paint booth is not just about prolonging its lifespan, but it’s also about ensuring the safety of your workers and the quality of your work. Regular maintenance can prevent costly repairs and downtime, making it a worthwhile

investment. Remember, a well-maintained dry paint booth is the backbone of any successful painting operation. We hope this guide has provided you with valuable insights and practical tips on how to maintain your dry paint booth effectively. Keep these guidelines in mind, and your paint booth will continue to serve you well for years to come. Happy painting!

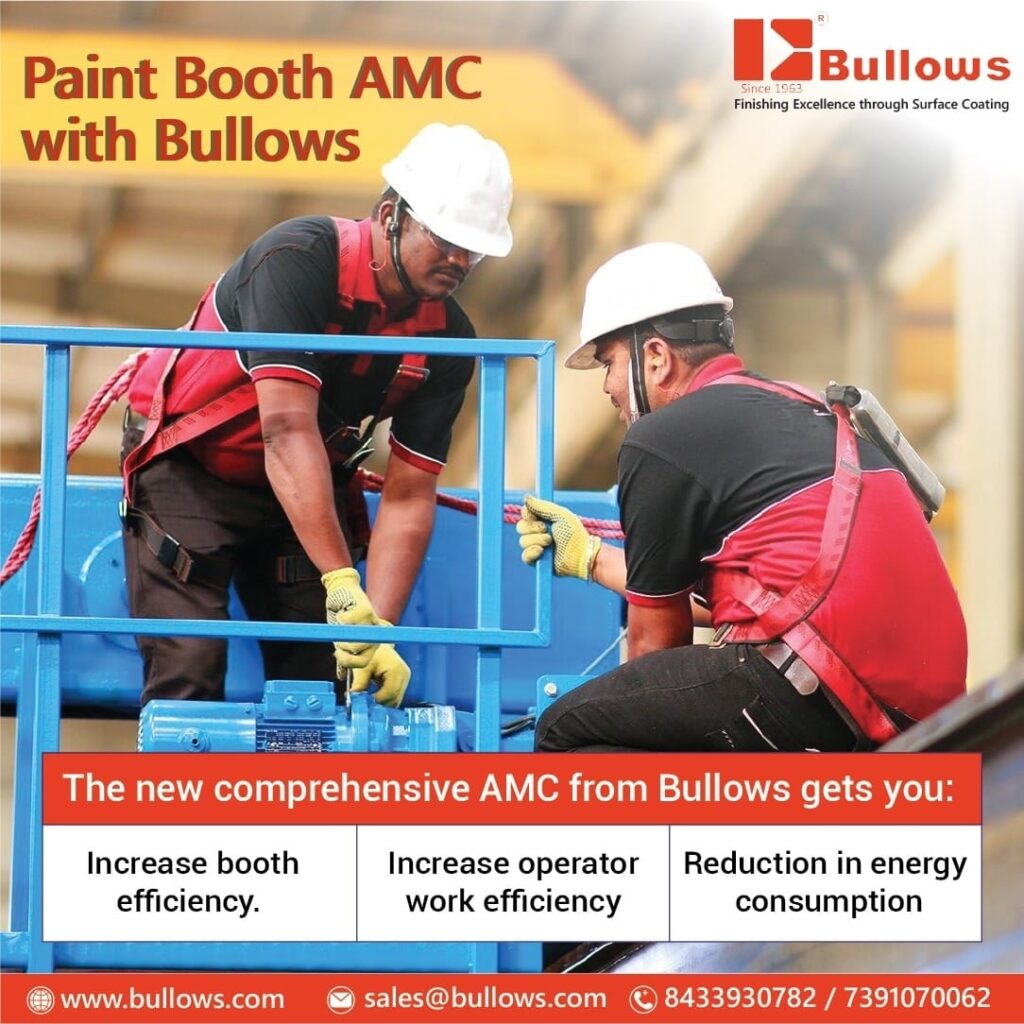

Experience the Advantage of Bullows Services & Product Today

Contact us today to learn more about Bullows maintenance services & health check-up of your paint booth, Spray Guns, Tanks & Paintshop Accessories. More over free consultancy services on Paintshop & Paintshop Accessories and how they can revolutionize your industrial coating applications. Experience precision, efficiency, and reliability like never before with Bullows – your trusted partner for excellence in spray painting technology.

Phone No: +91 64339 30782 / +91 73910 70062

Mail Id: sales@bullows.com

Website: www.bullows.com

WhatsApp: https://wa.link/62icut

I’m so happy to read this. This is the kind of manual that needs to be given and not the accidental misinformation that’s at the other blogs. Appreciate your sharing this best doc.